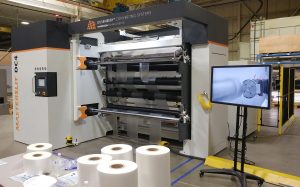

If you are wondering about techniques used by slitters to cut materials, you are in the right place. Slitter rewinders do not only cut in one way. There are at least three techniques they use to slit products.

The three techniques used to cut material by rewinders are:

- Razor blade

- Shear cut

- Score cut

Factors that determine the technique

The most appropriate technique to use depends on factors such as:

- The type of the material being slit

- The thickness of the materials that are being processed

Here is a deeper look at the three techniques mentioned earlier:

- Razor blade

This technique works best with light materials that are non-abrasive. It simply makes a razor slit in the air or in a grooved ball.

Advantages

- It is economical.

- It is fast.

- It is easy to set up.

Disadvantages

- It cannot cut through heavy, abrasive materials.

- It can burnish film at high speed.

- If there is a lot of heat, it can melt the film and create a bead which would interfere with the

- Shear cut

This technique uses two rotary knives that have the same effect as using a pair of scissors on paper. The technique is used on heavier gauge material, for instance:

- Thick film sheet

- Paper

- Foil

- Laminates

Advantages

- It gives accurate slit widths.

- Close tolerances

Disadvantages

- The set up must be precise.

- An ideal angle must be achieved at the junction of the blades.

- Score cut

Also known as the crush cut, the score cut is the oldest technique. It was first used in the slitter rewinder machinery and involves crushing the material to separate one part from the other. It achieves this using a dull knife which makes contact with a hard surface.

The technique is used for slitting materials which are which are pressure-sensitive. This is because it creates a non-sticky dry edge.

Advantages

This technique has one major advantage; it can be set up quite fast.

Disadvantages

- The dust that is set off while cutting paper using this technique can build up and cause problems for the machine.

- Should a defect appear while slitting plastic film and sheet, film stretching and deformities can form on the material. This would lead to rejection.

- It is likely to cause cracking when applied to hard plastic.

You can, therefore, determine which of the three techniques discussed is best suited for your application. Always remember that different projects have different goals. Also, keep in mind that there are different types of machinery which will use different materials and ultimately, different processes. When you set out purchase your slitter rewinder, ask the relevant questions and deal with the experts. There is nothing as frustrating as spending money on machines that cannot deliver what you need.

Run online checks by typing slitter rewinders, or even company names like Elite Cameron Slitter Rewinders and find out as much as you can while also comparing quality, prices and any other pertinent issues that are relevant to your purchase.

Pingback: The 5-Minute Rule for Elite Cameron Slitter Rewinders – Smart Arts Fund