Laser engraving is a term generally used to describe the use of a laser beam to engrave images and make inscriptions on objects.

It has also now been used loosely for any object marking that is done with the user. So, laser engraving, laser marking, and laser etching are often used interchangeably. However, these marking techniques are quite different.

This article provides a detailed guide on what laser engraving is and how it differs from other techniques done with the aid of a laser. We will also provide you with some tips on how to choose the top laser engraver for your company or business.

Let us start with a proper description of laser engraving:

What Is Laser Engraving?

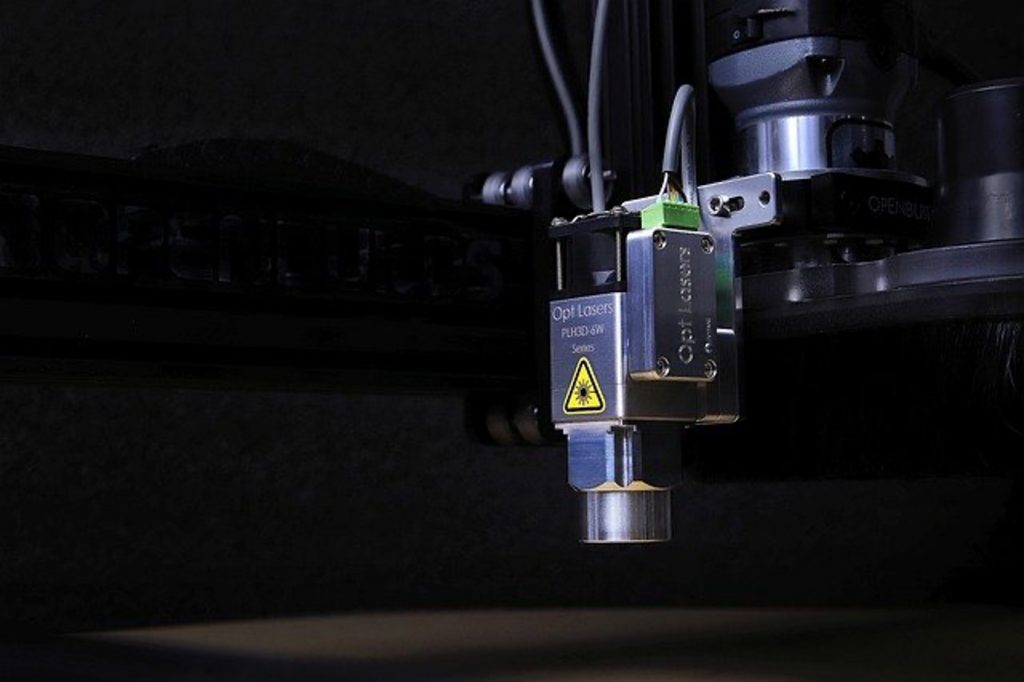

Laser engraving is a subtractive technique that is used to make changes to the surface of an object with the aid of a laser beam.

This technique is used to make images and designs that are visible to the human eye. So, no matter how small or big the image is, the human eye can see it.

In laser engraving, the hot beam from the laser will vaporize the area of contact on the object. The beam will then create cavities on the object to form the desired image or design.

Types Of Engraving Machines And How They Work

Thanks to the hot beam, engraving is a really quick process. So, except the design is complex, it will not be long before you get your desired outcome.

The depth of the engraved design is determined by the number of times that the beam goes over the object. The higher the frequency, the deeper the inscription.

There are three kinds of engraving machines.

The first kind is engraver machines that are designed in such a way either the object remains stationary, while the machine moves over the object to create the design or the machine remains stationary while the technician moves the object under the laser beam.

The second kind of engravers is those machines that are designed for cylindrical works.

The third set of engravers are machines where both the object and the machine remain stationary throughout the process while a set of mirrors called galvo mirrors are used to direct the laser beam to portions of the object that need to be engraved.

Laser Engraving vs Etching vs Marking

Laser etching is a popular subset of engraving. Unlike engraving where the beam vaporizes the area of contact, with laser etching, the beam melts the matter.

Also, instead of creating a carving on the item, it creates a raised cavity and alters the characteristics of the material at the area of contact. For instance, the modification can cause a contrast between the cavity and its surrounding area.

Of all the laser techniques currently being used, engraving is the most common for product branding and personalized customization. Click https://en.wikipedia.org/wiki/Laser_engraving to learn more engraving information.

Laser marking is a more general term that refers to any laser method that leaves marks on an object by charring, ablation, foaming, and chemical alteration. However, unlike engraving, the penetration, if any, is often minimal.

How To Choose Best Engraving Machine For Your Business

Nowadays, business owners can surf the internet for engravers and will easily find a list of beginner-friendly and simple machines to get the basic tasks done.

But as wonderful as having a variety of machines to choose from is, without the right information, you may find it difficult to make the right choice for your business.

For instance, software compatibility is a major issue that branding businesses may face. You do not want to have to spend hundreds of dollars on a machine only to discover that it limits your design creativity to certain software that you are probably not familiar with.

Not to worry, if you are in the market for an engraving machine for your business, the following 5 tips will guide you on how to make the right choice.

Here are the 7 factors to consider before you choose a laser engraver:

1. Price

The first thing to note about the machine is how much it will cost you. Generally, the price of engravers varies based on factors like brand, size, and functions. So, while it is not uncommon to find engraving machines that cost less than 250 dollars, some engravers can cost you up to $10,000.

This makes it important to work with a budget. However, it is important to note that the price of an engraver tends to increase as its features increase. So, all other things being equal, engraving machines that are on the high side of the price scale tend to offer more features and are often more suitable for complex tasks than the low-priced ones.

Now, this does not mean that you have to rob a bank to get good value. What matters is finding the machine that can deliver the kind of solution that your business needs.

2. Material Of The Object

Another factor to consider before you choose an engraver is the kind of materials that you will be working on. Some machines are only suitable for certain materials. Yet some are versatile.

If you only use one or two materials, then a machine is designed for such materials. You may, however, consider machines that are versatile if you work on multiple materials.

With that being said, it is important to note that versatile and multifunctional machines tend to be more expensive.

3. Size

The size of the engraver also matters. So, ensure that you choose a machine that serves the purpose you need it for but also fits properly into your space.

You can opt for a standalone engraver if you have enough real estate in your office to accommodate it. But if your space is small, then a small desktop machine may be more suitable.

Also, note that multifunctional engravers tend to be bigger and pricier than the ones with fewer functions.

4. Software Compatibility

When it comes to choosing an engraving machine based on software compatibility, you can either buy an engraver that can accommodate your existing software and the kind of work you do or buy one that comes with its software.

Oftentimes, even though they tend to cost less when buyers choose engravers that come with the included software, they may have compatibility issues where the software does not support the kind of work that they do. Click here to learn more about software compatibilities.

5. Connectivity

One other thing to consider is how the machine connects to a computer.

With most modern engravers, you will have the option to choose between wireless technology like WiFi or Bluetooth connectivity and wired technology.

If you do not mind having to do a little cable management, then wired connections may be suitable for you.

However, we recommend machines with wireless options to keep your space neat and tidy.

6. Bed Size

The bed is the area on the engraver where the material will be placed and properly aligned before the engraving begins. As you may already know, the larger the bed; the easier it is to accommodate materials of different sizes and vice versa.

Large beds also make it easy to engrave small objects in a batch.

7. Technical Support

Before you buy an engraving machine, you want to be sure that the manufacturer has a good customer support system where you can easily call about issues with the machine and receive prompt solutions.

It is also important to consider how frequent repairs and replacements occur. Other considerations to take note of include the ease of finding information about repairs, maintenance, and repairs.

Knowing this will help you determine the best machine to invest in and machines to completely avoid. As a rule, if you want to protect your peace of mind, avoid machines with nameless brands. They generally have no reputation to protect and can afford to be careless without fear of grave repercussions.

Conclusion

Laser engraving is a subtractive method of creating images and designs on a material with the aid of a laser beam. The hot beam from the laser creates cavities in the object to eventually form the design or pattern of choice.

Laser engraving can be done on different kinds of materials including wood, plastic, glass, and metals. So, it can be used for personalized customization and branding purposes.

If you are considering buying a laser engraver for your business then you need to take note of important factors like the price, size, software compatibility, connectivity, and the type of material that the machine can engrave on.

While it is normal to work with a budget when choosing a product, it is also important to consider all other factors before you make a choice. Ensure that you do not compromise on quality because of the allure of a low-price tag. Choose what will give you maximum value for your money and will serve your marking needs optimally.

Now that you know what to look for in an engraving machine, you can go ahead and make the most suitable choice for your company.