Even if you do not stop to realize (and appreciate) it, you are definitely surrounded by plywood. Almost every industry from “Construction” to “Shipping” is impacted by plywood one way or another.

What Is Plywood?

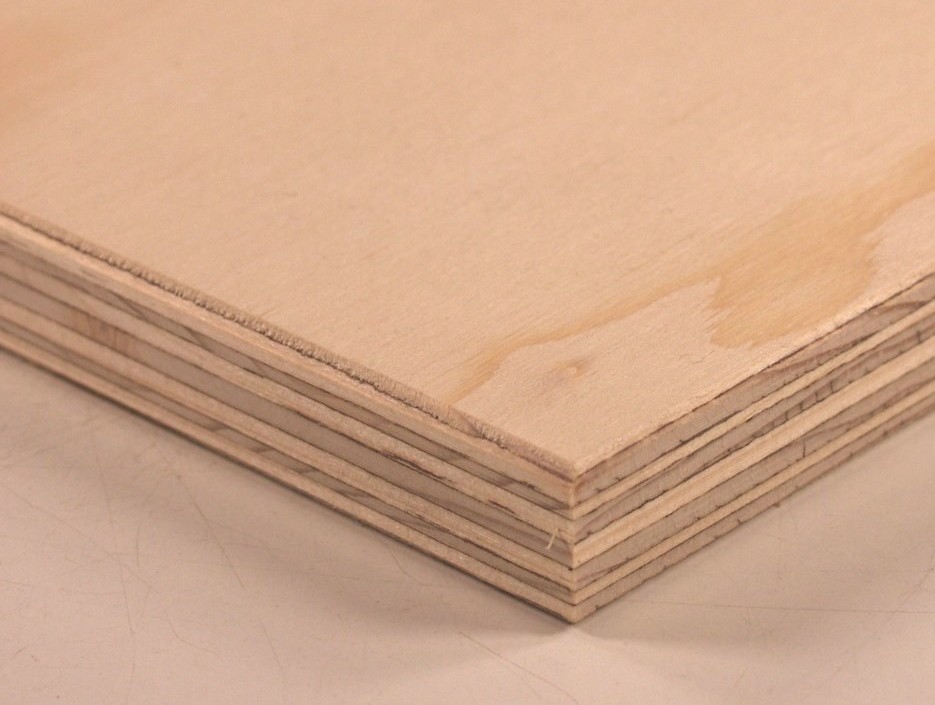

Plywood, as the name suggests, is a material derived from wood. Thin layers (veneers) of softwood (like pine) are cut using a veneer lathe. Then these are pressure glued together with each next layer of veneer being perpendicular to the latter. This means that their grains are perpendicular to each other. This is one of the reasons for the exceptional strength of the material.

“Timber Veneer” is actually the old name of plywood, which was renamed only in the last century. Here is its brief history:

The Ancient History Of Plywood

- Ancient Egypt

Plywood has a long history. It actually has an ancient history. The origin of this wonder material can be traced back to ancient Egypt. Deciphered hieroglyphics (the writing of ancient Egyptians) found on sculptures in Thebes describe the process of production and use of plywood. These have been dated to about 1500 B.C. during the reign of the pharos Thothmes III.

The production method is more or less the same as in nowadays. The veneer layers were cut by hand, back then. The various timber veneer sheets were usually selected with contrasting colours of wood. Glue was again applied after being heated. The pressure for gluing was a tad primitive – rendered by weighing the glued sheets together with sandbags. Only a few pieces of plywood furniture have been preserved until today. These have mostly been salvaged from temple and tomb excavations during the last century. They also represent irrefutable evidence of the early use of plywood.

- Ancient Greece

In her study, the American archaeologist Caroline Louise Ransom described evidence of the use of plywood for the making of furniture in Ancient Greece. It was also for “beautifying” ancient couches and chairs.

- Ancient Rome

Plywood was also found in ancient Rome. It now became material for the production of luxury, rather than an economical one as is today. Caesar was rumoured, to have especially valued an exquisite veneer drinking table. Later, a historian from the time of Augustus (63 B.C. to 14 B.C.) describes in detail that “veneers were cut and used, not for economy’s sake, but because in this way the most beautifully marked or figured specimens of wood could be selected and brought to the front. Thus a much more elegant and decorative effect was achieved compared to standard normal timber.”

Plywood During The Middle Ages

No written records are found about the use of plywood in the early years of the Middle Ages. It was not until the 18th century that veneer starts to be mentioned again. In 1760 one of the most important pieces of furniture – the “Bureau de Roi” was designed and made under the orders of King Louis XV. It took nine years to construct and was finalised in 1769. It is called “the plywood masterpiece” of the world.

Later on, during his war campaigns in Europe, Napoleon was always accompanied by his favourite rosewood veneer “Bureau de Campagne” (Campaign Desk).

The early plywood production was a costly and slow affair. The reason for this is that the veneer sheets had to be cut by hand. Hence only the rich could contemplate allowing themselves to acquire plywood furniture. Only they could marvel at the richness of texture and colour of the veneer. Commercial plywood suppliers were few.

Machine Production Of Plywood

Circular saws started to be used for veneer production in the early 1800s. This, however, did not make the process of plywood production much more efficient as more wood was wasted than finished veneers produced.

The first machine specifically designed to cut veneers was patented in the US in 1840 by John Dresser. Soon after that in 1865, the first plywood production patent was filed by John K. Mayo from New York. His patent describes plywood as commonly found today. Many more patents followed mainly for the various application of plywood in life. Such are:

- Use of structural plywood for bridges;

- Use of plywood for railroad tracks;

- Use of plywood as pavement;

- Use of plywood for docks, canal locks and of course a wide variety of furniture.

Plywood started to be used not only for creating luxurious furniture but also as a sound structural plywood material with application virtually anywhere.

Although initially “pasted wood” (as it was called then) was not easily accepted in the US, gradually its superior quality, endurance, texture, and yes … price started to make it the material of choice for furniture production. Plywood production factories, plywood suppliers and plywood distributors started to pop up all across the United States.

In 1928 the standard 4 by 8 feet (1.22 by 2.44 meters) was introduced in the USA for general building plywood sheets. These are still used today.

Present Days

The turn of the 20th century introduced plywood to door production. This was an instant hit as plywood doors were sturdier, thinner, stronger and yet lighter and cheaper than the standard ones.

It was in the 1930s when a waterproof adhesive was created. Marine-grade plywood started to be produced. It was not only a strong material made of wood, but it was also waterproof. This opened a whole new chapter of plywood usage. Boats, yachts and ships’ interior and exterior were now produced from the cheaper, stronger and more water-resistant plywood material.

Although plywood was already a low costing material, new spin-offs were also found which were even cheaper (though less sturdy). The 1960s saw the patent of the first particle boards being and MDF emerged. MDF suppliers quickly became popular again in the US and then gradually across the globe.

The issues of making delicate cuts in plywood were fixed with the advent of laser cutting technology to plywood production. Now custom laser cut wood panels are available complementing the standard large sheets. Melamine cut to size and particle boards cut to size were widely available.

The history of plywood is a long one. During these thousands of years, its applications were steadily increasing. We may only guess what the future holds for this wonderful material. Is it possible that habitats on Mars will be plywood constructions?