If you are involved in electronics manufacturing, you have probably come across the acronym PCBA and even needed to buy PCBA. So let’s walk through the important details of the PCBA.

Table of Contents

What is a PCBA?

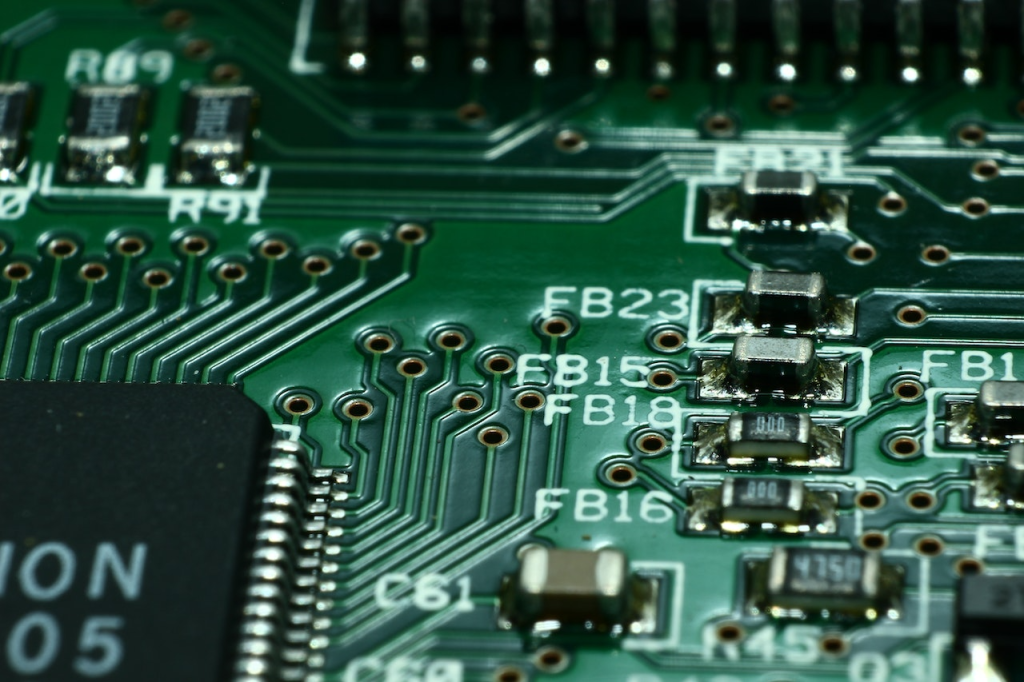

Several electronic devices today would not exist without the Printed Circuit Board Assembly (PCBA). The Printed Circuit Board Assembly (PCBA) houses and connects all components crucial for the running of electronic devices.

It connects components such as capacitors, resistors, integrated circuits etc.

The PCBA is composed of materials such as solder masks, substrates, copper and silkscreen. The copper foil of the PCBA is bonded to one side of a non-conductive substrate. Substrates are commonly glass-epoxy or plastic.

The Benefits of a PCBA

A Printed Circuit Board Assembly (PCBA) is a crucial component in any electronic device or appliance. It helps to interconnect components, provide electrical pathways and form the foundation of any electrical device. It can be used in a variety of applications, ranging from industrial applications to consumer products.

One of the major benefits of a PCBA is that it provides greater reliability and stability than its alternatives. This is because a PCBA consists of tightly-packed circuit elements, which are soldered onto the board, and sealed in place with protective layers. As a result, there is less risk of mechanical or electrical failure in comparison to alternatives such as wiring harnesses or discrete parts.

In addition, a PCBA offers greater flexibility for design, as it can be easily tailored to the requirements of each project. This allows for increased customisation and more complex circuitry, which can lead to more efficient products.

Finally, due to its compact design, PCBAs take up less space than conventional wiring harnesses, making them ideal for products with space constraints.

Overall, a PCBA offers numerous advantages when compared to other alternatives. It provides reliable connections with high levels of stability and flexibility in design, as well as saving on space. Therefore, it is an invaluable part of any electronic product or appliance.

How to Choose the Right PCBA

The PCBA is a sophisticated component that may be difficult for an average man to decipher. As a result, there are guiding principles to aid good choice of the appropriate PCBA for the right project.

Understand Your Needs

The Printed Circuit Board Assembly has a wide application range and it’s not a one- fit-all component. So the type of project at hand will influence your choice of appropriate PCBA.

Figure out your project and what it needs. For example some projects require a flexible PCBA while some may require a single layer PCBA. Then go for the PCBA ideal for your project.

Research Suppliers

These are sensitive devices and you need some assurances on quality. So it’s best to deal with suppliers with good track records showing the consistency of their PCBA quality. The suppliers should be able to offer support and guidance.

Test Your Design

A lot of words have been spoken, but it’s high time you get a practical view of what you are buying. Ensure you test the components and see that they are working fine.

Get Professional Advice

You can seek advice from experts in the field. Tell them about your project and they will guide you to picking the best PCBA for your project.

Conclusion

Choosing the right PCBA can be a daunting task, but by following these steps, you can make sure that your project is successful and that you get the best possible result from your PCBA. These steps include – understanding your needs, research suppliers, testing your design and getting professional advice.