If you want to try your hand at making jewelry making, in addition to the option of using an engraving machine to carve, there is actually another option, and that is etching, both of which are methods of the jewelry making process, but trying to figure out which is best for you is a tricky process that requires you to make a choice based on your own judgment. Next I help you understand the basics of these two techniques, I will give you a more detailed understanding of etching and engraving techniques, what are the principles involved in each technique, and let you make the most informed choice through the differences between the two.

Etching

Etching is a technology that may be unfamiliar to many people, but it is not new and dates back to the Middle Ages. Etching is traditionally a technique used mainly for printmaking, but it is also a technique that can be used to create metal patterns, and is therefore also used in jewelry.

How does etching work?

Etching is a technique that is suitable for use on a variety of metals, suitable for most metals such as copper or zinc. Generally, the surface of the metal plate will be treated with acid-resistant wax or “abrasive” first, and then the whole metal plate will be immersed in the acid solution, the surface of the metal which is not coated with acid-resistant wax or “abrasive” will be corroded by the chemical reaction with the acid solution, and the etching marks will be left after a certain period of time. The effect of the etching time is mainly related to the etching time and the concentration of the acid.

The disadvantages of etching: it is difficult to control the depth of etching to achieve precision, line contour compared to engraving does not have the advantage.

Advantages of etching: suitable for high-volume production, with high production efficiency.

As the technology is updated, there is also a new type of etching technology, that is, laser engraving. The principle of this process is again very different from the traditional etching method. Laser etching uses a high temperature beam to melt the material.

Precautions: the etching process requires the use of professional equipment and chemicals to operate, always follow the relevant safety guidelines in the operation process, the need for professional jewelry makers to guide the completion.

Engraving

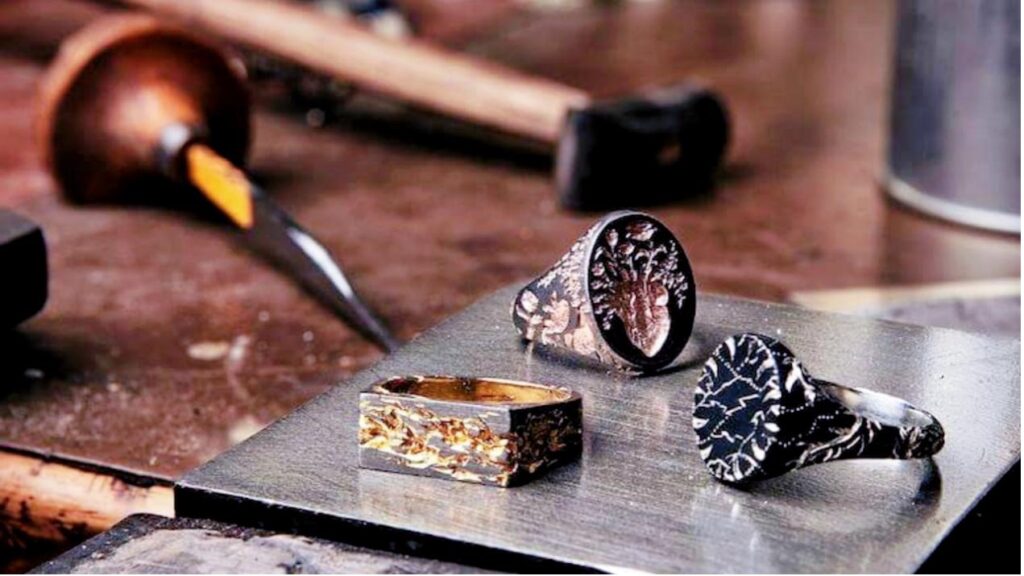

Engraving usually uses an jewelry engraving machine to transfer the designed pattern to the surface of the material, and then carve according to the designed pattern. The depth of engraving can be freely adjusted according to the needs of the engraver, resulting in a durable and highly visible pattern.

Disadvantages of engraving: It requires a lot of practice in engraving, and it is time consuming to engrave a fine work. It is therefore difficult for projects that require mass production.

Advantages of engraving: It has a very high degree of freedom and allows for more freedom in engraving patterns of varying depths and shades. Due to its unique production difficulties, it also has a higher value for the works of master engravers. Since the metal chips for engraving are removed directly from the metal surface by the vibration of the engraving knife, the resulting grooves are free of burrs and can be engraved with clear and beautiful lines.

Precautions: Engraving needs to follow the safety guidelines for engraving, such as the safe wearing of protective equipment such as goggles, and engraving tools need to be maintained and cleaned on a regular basis.

The difference between etching and engraving

Durability

Engraved jewelry has a higher durability, engraved jewelry has a higher durability, because the depth of the engraving will usually be deeper, need to be pressed through the very serious wear and tear before you can not see the engraved pattern.

Etched jewelry has less durability than engraved jewelry, as the etching is usually shallow and can be blurred by heavy wear and tear.

Material Selection

The choice of materials for engraved jewelry is usually more diverse, including metal, jade, wood and so on, the engraver can choose different ways of engraving according to different materials, such as grinding, drilling and so on.

Etching jewelry jewelry material selection is relatively more single, mainly silver, copper, stainless steel and other metal materials, and these materials can also be completed by engraving. Of course, it can also etch some materials that are not commonly used in the field of jewelry production, such as glass, metal, semiconductor materials and so on.

Applications

Etching and engraving in addition to applications in the field of jewelry production, in other areas also have a wide range of applications, both can provide customized services in industrial manufacturing, artistic creation, mold making, decoration, signage production and other fields play an important role, usually according to the cost, productivity and other aspects of the actual needs of the comprehensive consideration of the appropriate method, while the cost of engraving is relatively low, only need to spend a Engraving machine money you can start your engraving career, in the field of jewelry production engraving relative to etching has more advantages, if you are interested in engraving, now you can start your engraving journey.